Professional Services in Valve Industry: From Production to Post-Sale Support

Before, during and after manufacturing industrial valve products, it has been identified that the process itself is more important than the products themselves. B2B firms require good quality and reliable valves for their operational functioning; at the same time they also have the need for the various professional services that are associated with these valves. It is not only restricted to the product but how each valve is manufactured to the highest quality, right from the production process, to the after sale service that many industrial valves suppliers provide their customers. This paper describes the first the major professional services in the specified valve market using a broad perspective of valve, as well as, solutions from the swing check valves manufacturers and solutions they provide.

Precision in Production

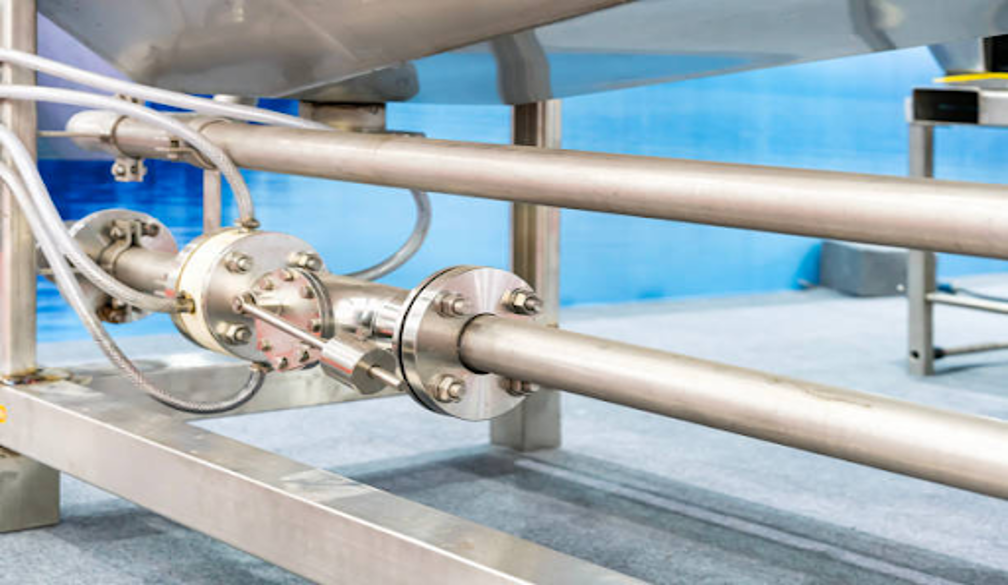

Thus in the context of developing a professional service in the valve industry the improvement on precision for the production effort should start. Almost all industrial valves because they are employed in different services involve having to possess specific characteristics and performance standards to enable them function optimally in the intended service such as in the oil and gas or water treatment sectors. This is best illustrated by the application of different manufacturing technologies including computerized numerical control, precision casting as well as quality assurance systems.

Therefore, to swing check valve manufacturers, during the manufacturing of the valves, the valves manufactured demonstrate the specifications that will help prevent the reverse flow in the pipelines which is essential in maintaining the integrity as well as efficiency of the system. In these points highest quality materials and tight manufacturing standards are used to create the valves that are capable of handling high working pressures, aggressive mediums, and reversal cycles. Evaluations of parts as far as manufacturing are important since valve suppliers ensure that their valves contain mechanical and material necessary for making the equipment service to the users lasting and dependable.

Technical Consultation Services

Technical consultation is among the common professional services that industrial valves’ suppliers provide in the market as extra services. But before producers make the purchase, they require advice for the type of valve that best suits their operations. This involves aspects such as the environment it operates in, its flow rate, pressure and compatibility with the other systems it is to replace.

Technical consulting services help B2B customers to prevent cases when valves are selected and used inappropriately, and receive products with the proper characteristics. For example, manufacturers of swing check valves in different geographical locations can provide information about which type of operations the check valves are appropriate for, for example water supply systems where backflow is undesirable or chemical circulation plants where backflow means the fluids are polluted. Customers receive professional advice that will help them to economize, eliminating possible issues in the systems with valves.

Customization and Special Solutions

Specialty valves for most of the industrial uses present themselves in valve problems that do not suit most of the intended business situations. This is where customization or special solutions continue to be part of the picture. Almost all leading industrial valves offer the customization services where businesses can modify the valves to fit their specific requirements such as changing the material, size or actuation type of the valve.

Integration is especially relevant to the manufacturers of swing check valves for a few reasons which are as follows; Integration is particularly helpful in satisfying the needs of industries using equipment with high constructive abilities, high temperature or highly active chemicals. Involvement of these manufacturers in offering such specific models can be a guarantee to clients on fine tuning their systems in factors such as effectiveness, security and durability. Customer services are about meeting clients needs that are not addressed by the product line and getting to the clients with valves that are suitable for specific uses.

Installation and Commissioning Support

Thus, selection and manufacture of adequate valves for the application are critical; installation and commission also forms part of the PAR. Service offering Most industrial valves suppliers offer their clients with installation and commissioning services. For instance, during installation, specialists can be offered to oversee this process and correctly design and join valves.

For the swing check valve manufacturers, confirming that these valves get used rightly makes it possible for the valves to perform a given task while fulfilling the requirement of backflow prevention without making them complicated by issues such as resistance or pressure drop. Installation and commissioning services help the valve suppliers to enable their clients commence the use of their equipment without common queries that arise from wrong installation processes at initial stages.

Comprehensive Post-Sale Support

This is in contrast to other business markets where the business and the supplier part ways when the latter delivers the product and makes an installation. As it will be seen later, giving massive support after a sale is usual in any valve business among worthy firms. It entails periodic check-up, requests for addressing different issues, supply of spare parts and training of clients’ personnel on how to use and maintain valves.

Such support is important mainly in industries that use severe or heavy duty valves which are likely to degrade due to use. As it is seen with suppliers of industrial valves that are also manufacturers of swing check valves they either provide maintenance services that consist of checking and replacement of certain parts of the valves to increase the life span of the valves and make sure that they are functioning appropriately. Valve suppliers also provide constant support to their clients in the sense that the latter always check on their systems to make sure that the breakdown times are kept to minimums.

The other main component of the value is the professional services which industrial valve suppliers are in a position to extend to their clients within the valve industry. Such services encompass accurate manufacturing, professional advisory services, designing, implementing and providing comprehensive after-sale services, to ensure the clients not only get good products but also the professional services that will help make their organizations optimal. Swing check valve manufacturers therefore hold potential to help increase B2B by providing advisory services related to the decision making process, system optimization and profitability. As such, these suppliers not only provide steam trap valves but also the opportunity to work with the suppliers for a lifetime and be confident in working with the product.