How to Select the Correct Size of Heat Shrink Tubing: A Comprehensive Guide

Heat shrink tubing is a versatile and essential component used in various industries to provide insulation, protection, and strain relief for wires, cables, and other electronic components. The tubing is made of a special material that shrinks when heated, forming a tight, durable seal. In this blog post, we will explore the ins and outs of selecting the correct size of heat shrink tubing, understand the concept of heat shrink ratios, and offer a heat shrink tubing size chart to help you make an informed decision.

What is Heat Shrink Tubing?

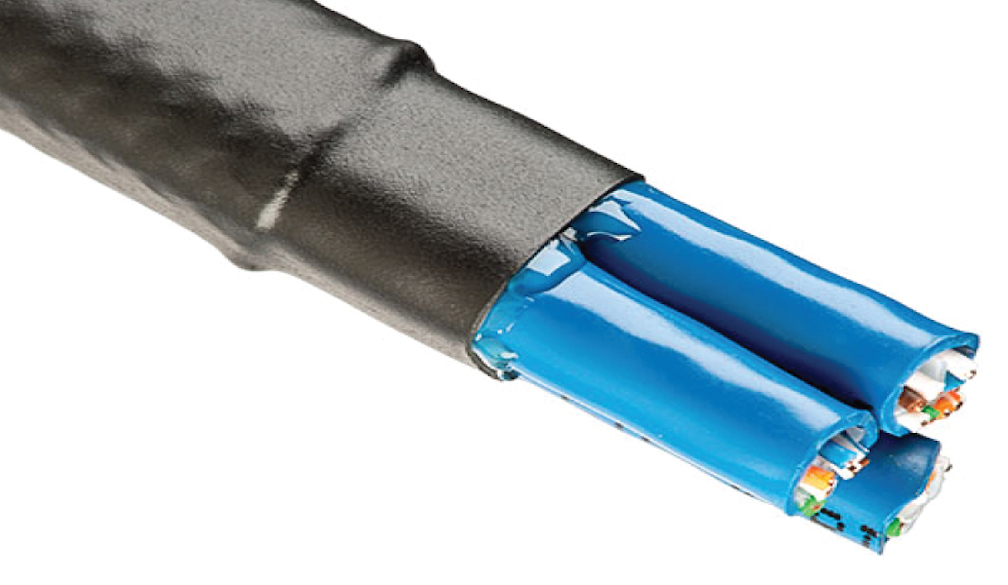

Heat shrink tubing is a type of polymer material that is commonly used to insulate electrical wires and components, offering protection from environmental factors such as moisture, dust, and physical wear. When heat is applied, typically using a heat gun, the tubing contracts and tightly wraps around the object it covers. This shrinkage results in a secure, durable, and waterproof seal that prevents corrosion and physical damage.

Heat shrink tubing is commonly used across electrical, automotive, telecommunications, and aerospace industries due to its effectiveness in protecting sensitive wiring and components from external factors.

Key Benefits of Heat Shrink Tubing:

- Insulation: It provides a protective layer that insulates wires from external environmental factors and short circuits.

- Protection: shields cables and components from abrasion, moisture, dust, and other harmful elements.

- Strain Relief: Assists in securing cables and wires to lessen the strain on the joints.

- Electrical safety: Prevents exposed wires, which lowers the likelihood of electrical accidents.

Heat Shrink Tubing Ratios: What You Need to Know

The size and shrink ratio of heat shrink tubing are crucial factors in determining how well it will perform in a given application. Heat shrink tubing is available in different shrink ratios, which refer to how much the tubing will shrink in diameter when heat is applied.

Common Shrink Ratios:

- 2:1 Shrink Ratio: The most commonly used ratio. When heated, the tubing shrinks to half its original diameter. This ratio is ideal for standard applications such as electrical wiring and insulation.

- 3:1 Shrink Ratio: The tubing shrinks to one-third of its original diameter. This ratio is suitable for applications where greater coverage or irregularly shaped components need to be insulated.

- 4:1 Shrink Ratio: The tubing shrinks to one-quarter of its original size, offering a snug fit around components that vary in size. It is ideal for situations where you need the tubing to adapt to multiple sizes of wires or connectors.

The correct shrink ratio for your application depends on the size of the wire or component you're insulating and the amount of shrinkage required.

How to Choose the Correct Size of Heat Shrink Tubing

Selecting the right size of heat shrink tubing is essential to ensure proper protection and a secure fit. Here are the key steps to determine the correct tubing size for your project:

1. Measure the Diameter of the Object to Be Insulated

Start by measuring the diameter of the wire, cable, or component that you plan to cover with the heat shrink tubing. It's essential to choose tubing that is slightly larger than the component to allow the tubing to fit over it.

For example, if you have a wire with a diameter of 10 mm, you should look for tubing that has an outer diameter slightly larger than 10 mm, allowing you to slide the tubing over the wire.

Quick Tip: Please take note that our heat shrink tubing diameters are measured as ROUND TUBE, NOT FLAT.

2. Consider the Shrink Ratio

After determining the diameter, consider the shrink ratio of the tubing. Tubing with a higher shrink ratio (3:1 or 4:1) might be required if you are working with smaller or irregularly shaped components. For typical wiring or connectors, a 2:1 shrink ratio is often sufficient.

3. Account for the Final Size After Shrinking

Next, calculate the final diameter of the tubing after it shrinks. For example, tubing with a 2:1 shrink ratio will reduce to half its original size when heated. If you want the final fit to be snug, you’ll need to ensure that the tubing’s size will reduce appropriately.

4. Check the Length of the Tubing

Besides selecting the correct diameter, ensure that the length of the heat shrink tubing is sufficient to cover the entire length of the wire or component. You’ll want to make sure there is enough tubing to cover the wire’s exposed area and any connectors.

5. Select the Right Material

While selecting the size, you should also consider the material type. Heat shrink tubing comes in various materials like polyolefin, PVC, and fluoropolymer. Polyolefin is the most commonly used due to its flexibility, abrasion resistance, and low shrink temperature.

If you want your wires, cables, and components to function at their best and be protected, you must choose the appropriate size of heat shrink tubing. It is critical to comprehend shrink ratios, consider diameter, and select the appropriate material to make an informed choice. By following the guidelines provided and consulting the heat shrink tubing ratio, you can ensure that you select the best option for your specific application.