How Hard Chrome Plating Strengthens Industrial Components And Improves Long-Term Performance

Industrial machinery, tools and metal components operate under constant pressure, friction and exposure to harsh environments. To ensure these parts remain durable, precise and efficient, many industries rely on hard chrome plating as a trusted protective solution. This specialised process applies a dense chromium coating over metal surfaces, enhancing their wear resistance, reducing friction and significantly extending their operational life. Hard chrome plating has become essential in manufacturing, engineering, automotive, mining and countless other sectors where strength and reliability are critical.

Why Hard Chrome Plating Is A Reliable Choice For High-Performance Environments

Hard chrome plating provides a unique combination of hardness, corrosion resistance and surface smoothness that makes it invaluable for heavy-duty applications. Unlike standard coatings, the chromium layer forms a robust barrier that protects metal components from physical stress, impact, abrasion and chemical exposure. This protection ensures consistent performance even under demanding operational conditions. Industries that depend on machinery for continuous production prefer hard chrome plating because it maintains efficiency while reducing the risk of unexpected failures or costly downtime.

Improving Wear Resistance For High-Friction Machinery Parts

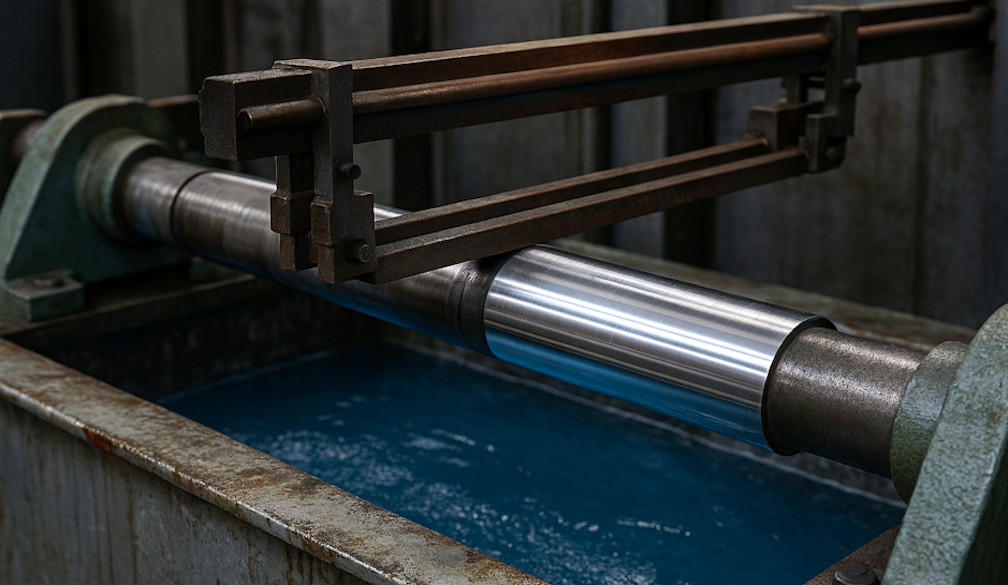

Machinery components that experience constant friction—such as rods, rollers, dies, fast-moving tools and hydraulic parts—are prone to wear and surface degradation. Hard chrome plating improves wear resistance by creating a tough, low-friction surface that reduces metal-to-metal contact. This helps parts maintain their shape and function over extended periods, even in high-speed or high-pressure environments. The reduced friction also lowers heat buildup, preventing premature wear and enhancing the overall safety and stability of the system.

Enhancing Corrosion Protection For Harsh Industrial Settings

Moisture, chemicals and environmental exposure can cause metal surfaces to corrode, leading to weakening and eventual failure. Hard chrome plating forms a corrosion-resistant layer that protects components from rust and oxidation. This is particularly valuable in industries such as marine engineering, mining, food processing and heavy manufacturing, where exposure to corrosive substances is common. By shielding metal parts from damage, the plating ensures a longer lifespan and more reliable operation in challenging environments.

Supporting Dimensional Accuracy In Precision Engineering

Precision is critical in industries that rely on exact measurements and tight tolerances. Hard chrome plating provides a controlled coating thickness that can be accurately applied and finely polished to achieve precise dimensions. This makes it ideal for components such as moulds, pistons, shafts, valves and specialised engineering tools. After plating, technicians can grind and finish the surface to the required specifications, ensuring the component fits perfectly into its intended application without compromising performance.

Restoring And Reconditioning Worn Components

One of the most beneficial uses of hard chrome plating is in the restoration of worn machinery parts. Instead of replacing entire components—which can be expensive and time-consuming—engineers can rebuild the worn areas with chrome plating and grind them back to original specifications. This process restores the part’s functionality, extends its service life and significantly reduces replacement costs. Businesses that operate large-scale machinery often rely on this method to minimise downtime and maintain productivity.

Offering Versatility Across A Wide Range Of Industries

Hard chrome plating is incredibly versatile, making it suitable for components made from steel, iron, copper and other metals. It is widely used in sectors such as aerospace, automotive manufacturing, toolmaking, printing, power generation and mining. Components such as bearings, engine parts, industrial rollers, hydraulic rods and pressing tools benefit from the enhanced durability and performance the plating provides. This versatility makes hard chrome plating a go-to solution for improving reliability across diverse industrial applications.

Providing A Smooth, Professional Surface Finish

The final finish of hard chrome plated components is not just visually refined—it also improves mechanical performance. The smooth surface reduces drag, enhances sliding performance and ensures stable movement between interacting parts. This is especially important in machinery that relies on tight coordination between components, such as hydraulic systems, precision tooling and automated equipment. A smooth surface finish helps maintain consistent operation and reduces the likelihood of jamming or mechanical failure.

Reducing Long-Term Maintenance Costs For Businesses

Regular maintenance and part replacement can be expensive and disruptive. By extending the life of metal components, hard chrome plating reduces the frequency of repairs and replacements. This results in lower operational costs and improved productivity over time. Industries with heavy machinery benefit significantly from these savings, as the lifespan of key components is greatly increased. The reduced downtime also contributes to smoother workflow and better performance across production lines.

Supporting More Sustainable Industrial Practices

Hard chrome plating plays a role in sustainability by helping businesses reduce waste and enhance resource efficiency. When components last longer and require fewer replacements, fewer raw materials and manufacturing processes are needed. This reduces the environmental footprint associated with producing new parts. Restoring worn components through chrome plating also conserves resources and supports environmentally conscious manufacturing practices.

Conclusion

Hard chrome plating remains one of the most effective ways to protect, strengthen and enhance metal components across a wide range of industries. Its ability to improve wear resistance, reduce friction, enhance corrosion protection and restore worn surfaces makes it indispensable for maintaining efficient and reliable machinery. For businesses looking to increase durability, reduce maintenance costs and support long-term performance, hard chrome plating offers a proven and valuable solution.