The Evolution of Cable Ties: From Invention to Modern-Day Applications

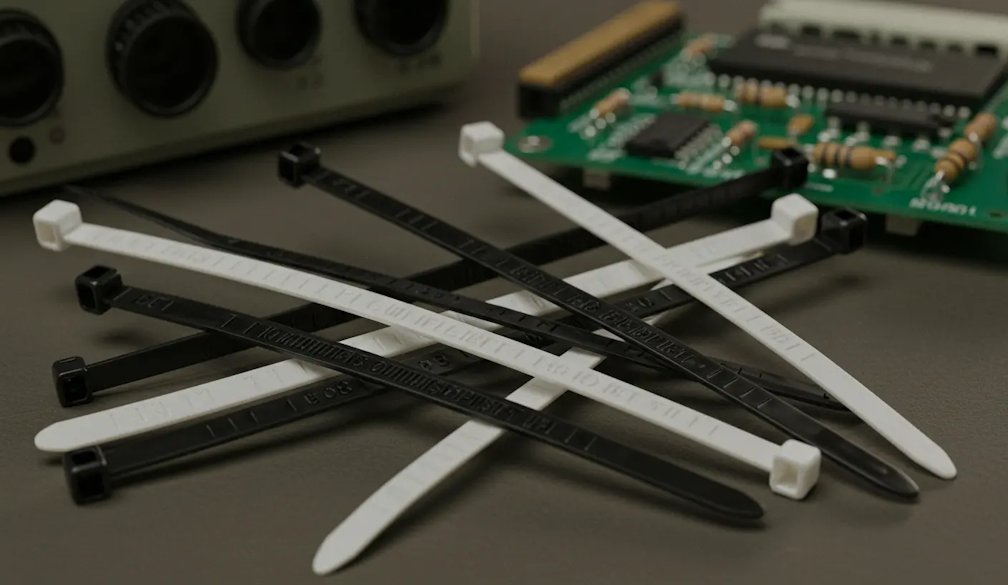

Zip ties, also known as cable ties, are now essential tools in many homes and businesses because of their strength, durability, and ease of use. This blog delves into the history of zip ties, explores their different applications, and examines the various types available today.

History of Zip Ties

The invention of zip ties began in 1958 when Thomas & Betts engineer Maurus C. Logan noticed how difficult it was to bundle cables in the production of airplanes. Logan created the first zip tie, originally known as Ty-Rap, in search of a more effective way to do it. The original design's metal locking tooth was later secured with nylon to increase flexibility and lower production costs. This invention quickly found uses in several other industries after revolutionizing cable management in the aerospace sector.

As manufacturing processes advanced, zip ties evolved to incorporate different materials and locking mechanisms to meet the demands of various industries. The creation of UV- and heat-resistant types further expanded their use in hot and outdoor environments. Zip ties can be used for various purposes because they are now produced in many different sizes, colors, and tensile strengths.

Various Uses of Zip Ties

Zip ties are well known for their adaptability and are used in many different contexts, such as:

- Cable management is the process of arranging and fastening electrical cables in homes and businesses to keep them safe and avoid tangling. Efficient cable management helps maintain the organization and reduces the risk of electrical hazards.

- Automotive Industry: To keep things organized and avoid interfering with moving parts, hoses, wires, and other parts must be secured inside cars. For fixes that are either temporary or permanent, mechanics and automotive professionals frequently use zip ties.

- Construction: Helping with various rigging tasks on job sites, securing temporary fencing, and bundling materials. Their durability and strength make them important tools for construction workers.

- Gardening includes repairing fences or trellises, training vines, and supporting plant structures. Gardeners use them to protect plants to stakes and prevent damage from wind or pests.

- Law Enforcement: Due to their strength and ease of use, they are utilized as temporary handcuffs. Law enforcement and security professionals use the Flex Cuff Zip Tie to control crowds in emergency situations.

- Commonplace Home Use: repairing damaged objects, arranging implements, and even acting as temporary hangers or handles. Zip ties are best suited for quick repairs and organizing household essentials.

- In an emergency: First aid kits are used to secure bandages or splints when medical tape is unavailable. Because of their durability, they're a reliable option in survival kits.

The adaptability of zip ties makes them a staple in toolkits and households worldwide.

Types of Zip Ties

To cater to the diverse needs across industries, various types of zip ties have been developed:

- Nylon Zip Ties: The most widely used type of zip tie is standard nylon, which is renowned for its strength, flexibility, and affordability. Suitable for general-purpose use in both indoor and outdoor environments.

- Reusable Zip Ties: Made with a release mechanism, these ties can be used again in situations requiring modifications. They minimize waste and are environmentally friendly.

- Stainless Steel Zip Ties: Suitable for heavy-duty applications in the industrial and marine sectors, these ties are made of stainless steel and provide exceptional strength and resistance to corrosive environments and extreme temperatures.

- Colored Zip Ties: Zip ties are available in multiple colors for coding and identification purposes, which helps arrange cables and components systematically. Frequently utilized in the networking and IT sectors.

- UV-Resistant Zip Ties: Zip ties which are manufactured with UV-resistant materials can withstand exposure to sunlight, suitable for outdoor applications such as landscaping and signage installation.

- Heat-resistant zip ties: Made to withstand high temperatures, these are frequently found in settings such as manufacturing facilities, engine compartments, and aerospace applications.

- Metal Detectable Zip Ties: These ties are essential for avoiding contamination in the food and pharmaceutical industries because they contain metal particles that can be identified by standard metal detection equipment.

- Double-Headed Zip Ties: These ties have two locking heads that make it possible to bundle and arrange several cables or items more securely.

Selecting the appropriate type of zip tie is crucial for ensuring safety and effectiveness in specific applications.

Importance of Zip Ties

Zip ties are important because they offer a straightforward yet efficient way to bundle, secure, and arrange objects. Their strength, durability, and ease of use make them indispensable for preserving safety and order in a variety of contexts. Zip ties help to prevent hazards and ensure efficient operations in a variety of industries, including electronics, construction, automotive, and aerospace.

Furthermore, they are an economical option for personal and business use due to their accessibility and affordability. They are essential for quick fixes and do-it-yourself projects, and businesses usually rely on them for safety, packaging, and logistics. The growing demand for sustainable and biodegradable zip ties further emphasizes their evolving role in environmental consciousness.

Since their inception in the late 1950s, zip ties have developed into multipurpose instruments essential to a wide range of uses. Choosing the appropriate zip tie for a given situation can be made easier by being aware of its history, different applications, and types, which will guarantee effectiveness and security in both personal and professional settings.